Even while assembling the movement of your timepiece, our watchmakers perform continuous tests and tweaks to ensure the best possible timing rate when it leaves their watchmaking bench.

Once assembled, the movement and then the fully cased timepiece are subjected to a battery of checks and tests that take place over 15 days.

Timing rate and power reserve

We test the rate, average daily variation and amplitude of the uncased movement in six different positions (6 vertical and 2 horizontal) continuously over 48 hours (46 hours in the case of Logical One) so as to simulate daily wearing of the watch.

We then place the movement in its case and repeat the same tests. We also conduct tests to guarantee the movement’s power reserve.

Winding and setting mechanism

Our watchmakers test the winding mechanism and time-setting mechanism to ensure proper, smooth functioning. For the automatic movement of Insight Micro-Rotor, we place it in a special winder and monitor that the micro-rotor is performing optimally.

Water resistance

To test and validate the water resistance of your timepiece, we subject your fully cased watch to the static pressure equivalent to its stated depth using a latest generation Greiner Vibrograf Poseidon LT-100 machine.

Prestige HM and HMS are tested to 1 bar, equivalent to the static pressure at 10 metres underwater. Logical One and Logical One Secret are tested to 3 bar, equivalent to the static pressure at 30 metres underwater. Insight Micro-Rotor 5 is tested to 5 bar, equivalent to the static pressure at 50 metres underwater.

Aesthetic examination

Our watchmakers and then Romain Gauthier himself inspect each finished timepiece for aesthetics under magnification.

Receiving your timepiece

We deliver your watch in a luxury, hand-made presentation case

Find out more

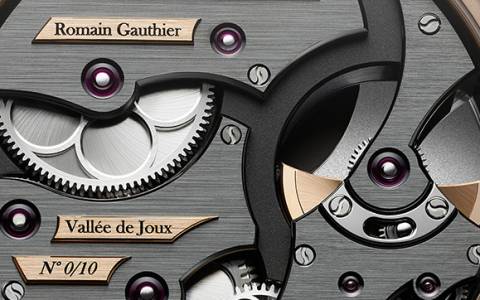

Logical One calibre

Logical One calibre

Insight Micro-Rotor calibre

Insight Micro-Rotor calibre

Prestige HM & HMS calibres

Prestige HM & HMS calibres

C by Romain Gauthier calibre

C by Romain Gauthier calibre